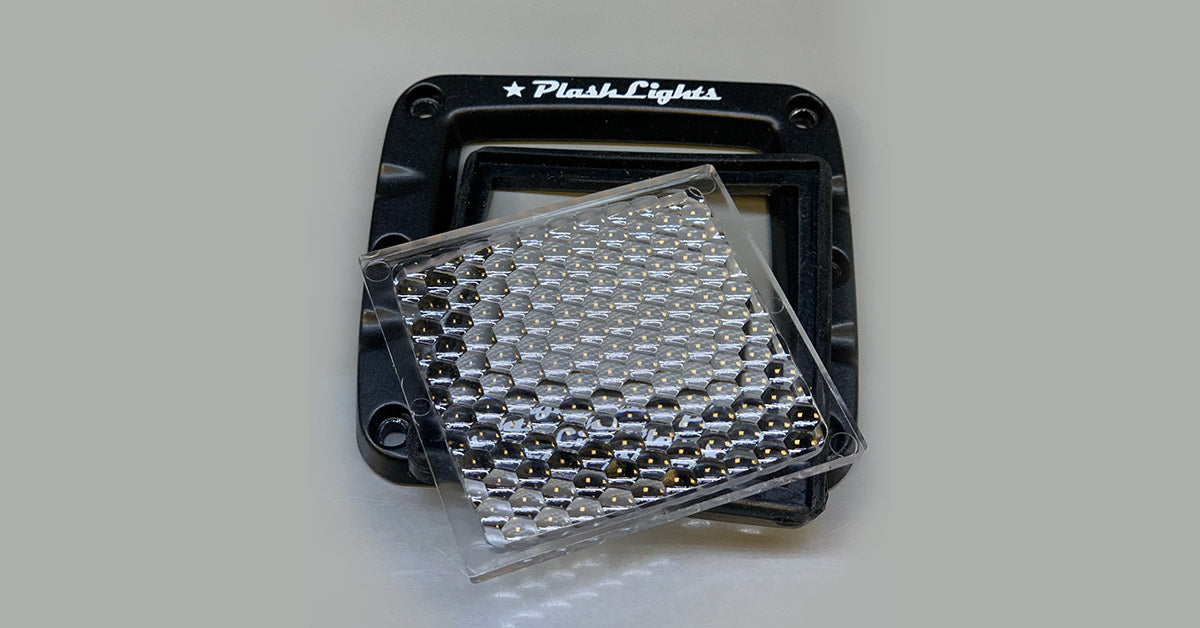

Lexan serves as an essential material for the creation our marine led lights and countless modern products, so much so that you’ve probably used an item made with Lexan today without even knowing it. But how, you may ask, can the same material be tough enough to stop a bullet and yet flexible enough to help create something as delicate as a DVD? The answer lies in Lexan’s unique chemical makeup and in a development process that led to it becoming one of our world’s most valued and widely-used plastics.

Lexan Basics

First off, it’s important to note that Lexan is a brand name and not the name of the material itself; the term “Lexan” has simply become synonymous with said material in the same way that Band-Aid has for bandages. That branding was formulated in 1960 by General Electric (GE), the company responsible for pioneering American development and production of the material. Bayer, meanwhile, has been creating the material under the name of Merlon (later Makrolon) since 1958; both companies discovered their version of the plastic within a week of each other and agreed to cross-license its manufacture so as to allow further development on both sides of the Atlantic.

None of that, however, gets into what Lexan actually is. Lexan is a polycarbonate resin thermoplastic. In a nutshell, what that means is that it’s a solid substance that can deform in extreme heat (typically 147 degrees Celsius, or 297 degrees Fahrenheit) and whose molecules are comprised of repeating subunits. Lexan is but one of a family of thermoplastics whose main claim to fame is in its ability to undergo significant deformation without cracking of breaking. What’s more, when fully formed, the polycarbonate sheet boasts an impact strength 250 times greater than that of glass and 30 times greater than that of acrylic (a similar thermoplastic). This strength and flexibility has made Lexan sheets an indispensable material for a wide variety of quality lighting manufacturers, as very few materials can claim Lexan’s transformative ability along with its outstanding heat and impact resistance.

Benefits and Uses

Those resistances, however, are but two of the attributes that have made Lexan such a popular and celebrated material. The polycarbonate's remarkable features include…

- High level of impact resistance (250 times the impact resistance of glass)

- Low rigidity and can be bought in flexible grades

- Can handle temperatures up to 240 degrees Fahrenheit before deforming

- Highly resistant to acids and other chemicals such as gasoline

- Can be drilled without worry of cracking

- Can be cold formed or bent without heating

- Low level of flammability

That is not to say, however, that Lexan is a perfect material. There are a few tradeoffs that manufacturers are forced to accept for this level of flexibility and all-around strength, tradeoffs that include…

- Easier to scratch than glass and some other thermoplastics

- More expensive than glass and some other thermoplastics

- Poor clarity, cannot be polished to restore clarity

- Can be yellowed over time by UV rays

- Low level of resistance to abrasive cleaners and surfaces

- Can be dented easily

Generally speaking, these attributes make Lexan polycarbonate an excellent material for applications where you’re not as concerned about aesthetics as you are about creating an extremely resistant protective surface. However, PlashLights is concerned about both and we have added a UV protective coating on the outer face of our Lexan lens to prevent the yellowing effect.

Conclusion

Lexan’s wide range of capabilities make it nothing less than a modern marvel, a material with infinite applications that enjoys prominent usage around the world. That said, it should be noted that not all Lexan is created equal; that is why we use the highest quality American made Lexan for our lens material. If you have any further questions regarding Lexan or our products, please feel free to get in touch with one of our knowledgeable technicians.

Thank you A&C Plastics and CJG Material Solutions for the information.

- PlashLights

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.