Throughout the history of the LED light the housings have been constructed from cast aluminum. This has been the "go to" material due to its low cost, simplicity to form custom shapes in casting, and its ability to dissipate the heat. The problem with cast aluminum is that the grade of the material cast is not very good. Meaning that it has high corrosive tendencies that are amplified in a corrosive environment such as saltwater. On top of that the thermal properties are fair, but when the aluminum is powder coated/painted or corroding those properties are diminished significantly.

This materials failure inspired me to find a better way to make it last. We tried every pre-treatment and marine coating that we could, sparing no expense. While better coatings did extend the materials lifespan, it still ultimately failed. So then I turned to the people that make the cast aluminum and I asked the foundry to cast using a 6,000+ grade aluminum (the same type of aluminum that is used in extruding to make the t-tops pipes) and their response was "we cannot do that." Then I asked them "how can I make cast aluminum last in a saltwater environment?" The foundry representative replied "that's simple. Do not use cast aluminum!"

Alright. No cast aluminum. Why cast at all? I will try machining and high grade aluminum such as billet. Or why not titanium. If you're going to make it make it the best right? Well, here's why... machining cost is very expensive. Titanium is through the roof expensive. This would increase the final price 10 fold. It is not feasible. So I started exploring other material such as composites, plastics, epoxies, etc. What I found is that while they have excellent corrosion properties, but little to no thermal properties. Until I found a special blend of carbon fiber. This type of carbon fiber dissipates heat 4 times better than aluminum (high grade aluminum, not flaking cast aluminum) and two times better than copper and has excellent corrosion properties! I'm still not sold though. There has to be a catch right... yep, it's super expensive. However, I decided that with engineering we could use very little of this material because its thermal properties are so great to achieve a better W/mk rating than any other light housing. Because of this, in September of 2018 the process of designed a carbon fiber light housing began.

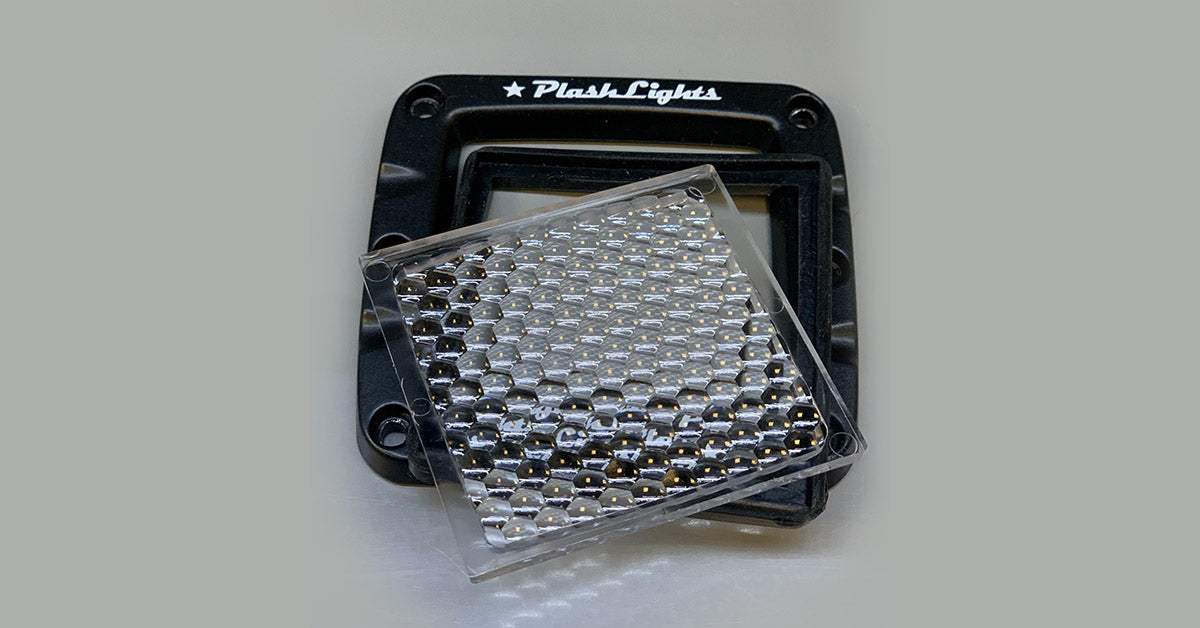

Below is a short video of the first light we made out of carbon fiber, the Corpus LED Deck Light. Released in February 2020.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.